Storing items is nothing new as we have all seen it in our house. From food items to cleaning agents, we have all these stored in our house. But it is not only the houses that store products. From distributors to stores, from warehouses to manufacturing units, every facility stores some items. Each of these items is purposed for regular use or occasional maintenance or emergency cases. This whole setup of storing also happens to be something special. Some of these items are heavy while some of these are delicate. Then there are some toxic materials that should be both carefully stored and used. Among the delicate items, bearing happens to be one.

Though made of metal, these can deform or get affected by different factors. From vibration to moisture, there are too many things that can cause complete or partial damage to the bearings. When stored and used carefully, there is scarcely any chance of any damage. Along with storage, it is always necessary to use proper tools like skf bearing puller (ตัว ดูด แบ ริ่ ง, term in Thai) and induction heater.

Avoid corrosion

Corrosion is something that is problematic for any kind of bearings. In fact, it can happen even during storage. As these are Meta made, they are vulnerable to moisture. The place where the bearings are stored must be a dry one so that the bearings do not come into contact with any moisture. Rust will ultimately damage the bearings leaving them to be no good for use. It can also cause premature failure which will affect the performance and productivity of the machine. The failed bearing will cause increasing operating costs. As perspiration can also cause corrosion, it is necessary to use gloves while using the bearings.

Keep them away from vibration

Vibration is something that can happen in a manufacturing unit. While storing the bearings, it is necessary to make sure that the storage is never affected by the vibration from nearby machineries. It can cause subtle changes to the bearings which will affect its performance.

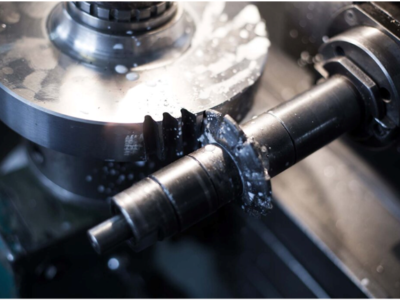

It is necessary to ensure proper mounting and dismounting

Dismounting the used bearings and replacing them with stored ones require some care and expertise. Bearings that have been stored properly can falter due to mounting issues. Tools such as skf bearing puller (ตัว ดูด แบ ริ่ ง, term in Thai) are necessary for the procedure to avoid any wrong or extra force. Overheating the bearing for mounting is another problem. The limit of temperature that a set of bearings can tolerate depends on it heat treatment.

Overheating will cause deformation or softening of bearing steel. It will lower the capacity to tolerate the load which will ultimately result in a failure. Induction heaters are necessary to heat the bearings to a certain level before mounting. An open flame is never an option to heat bearings. Lubrication is the key to healthy bearings. Choosing the type and amount of lubrication is necessary to ensure long running bearings. Always choose the manufacturer’s recommended lubricant so that the bearings can work properly.

Comments